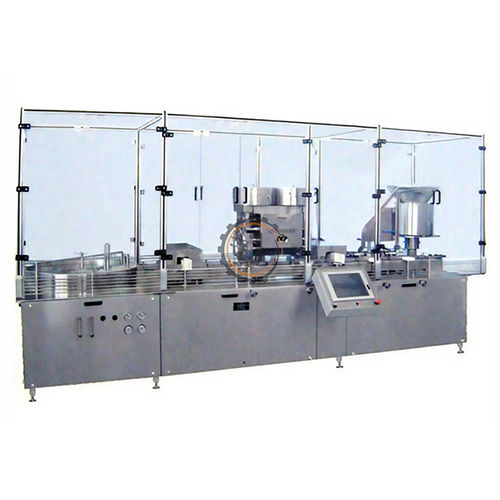

Automatic High Speed Injectable Powder Filling With Rubber Stoppering Machine

Product Details:

- Material Stainless Steel

- Computerized No

- Automatic Grade Semi-Automatic

- Control System Frequency Speed Control

- Drive Type Electric

- Voltage 420 Volt (v)

- Feature High Efficiency

- Click to view more

Automatic High Speed Injectable Powder Filling With Rubber Stoppering Machine Price And Quantity

- 850000 INR/Unit

- 1 Unit

Automatic High Speed Injectable Powder Filling With Rubber Stoppering Machine Product Specifications

- Frequency Speed Control

- No

- High Efficiency

- Semi-Automatic

- Stainless Steel

- 420 Volt (v)

- 1 Year

- Electric

Automatic High Speed Injectable Powder Filling With Rubber Stoppering Machine Trade Information

- Cash in Advance (CID)

- 2-3 Unit Per Month

- 10-15 Days

- All India

Product Description

This Automatic High Speed Injectable Powder Filling With Rubber Stoppering Machine is designed to provide high efficiency in filling and stoppering of injectable powders. The machine is made of durable stainless steel material and operates on electric drive type with a voltage range of 200-400 volts (v). The frequency speed control system ensures accurate and consistent filling of powder into vials or bottles. The semi-automatic grade allows for easy operation and monitoring of the filling process. With a warranty of 5-10 years, this machine is a reliable investment for pharmaceutical manufacturers and suppliers seeking to improve their production process.

Technical Specifications:

|

Model |

SPECIFICATION |

|

Direction |

Left To Right |

|

Production Rate |

Up to 240 fills / Min for Single Dose. |

|

Fill Capacity |

50 mg 1.5 grms. Single Dose (with Change Parts) 1.5 grms to 6 grms. Double, Triple and Four Dose. Fill range depending upon vial opening and bulk density of powder. |

|

Accuracy |

2% depending upon consistency and the Uniformity of bulk density of powder Under controlled level of Humidity (i.e. 35%) |

|

Electrical Supply |

1.00 HP For Main Drive. |

|

Power Requirement |

440 Volts, 3 Phase (4 wire System) 50 Hz. |

|

Height of Conveyor |

Adjustable from 900 to 950 mm |

|

Diamensions |

3759 mm (L) x 1242 mm (W) x 1885 mm (H) |

|

Net Wight |

1400 KGS. (Approx.) |

|

Gross Weight |

1850 KGS. (Approx.) |

Input Specifications:

|

Vial Diameter |

25 mm to 38 mm Max. |

|

Height |

75 mm Maximum. |

|

Rubber Stopper |

20 mm Diameter. |

Call Me Free

Call Me Free